CUSTOM RIM MOLDING AND ENGINEERING SERVICES

CUSTOM RACTION INJECTION MOLDING SERVICES

MOLDED SOLUTIONS® DON’T JUST HAPPEN,

THEY ARE DESIGNED.

Many designers and mechanical engineers design a part with custom plastic reaction injection molding, thermoforming, or perhaps sheet metal fabrication in mind. When you bring your ideas to our custom RIM molding and engineering team, you can rest assured that your polyurethane part will be designed and molded to the highest standard and with the highest possible efficiency.

DESIGNING FOR RIM

We will be glad to walk you through the process of RIM molding design.

Just send us your CAD file by e-mail or through our secure file upload link and we will provide you initial feedback – usually within 24 hours.

Getting to a RIM-feasible design takes 3 simple steps.

As shown in the graphic below, it starts when you send us your CAD file. Together we will perform 3 simple steps:

- Design Review for technical and economic feasibility. We will send you our design recommendations.

- You review our design proposal, confirm the feasibility of the design adjustments, and update your CAD files.

- With design adjustments implemented we continue with the design review with more detailed steps 1 and 2 (if needed) until your part is feasible for custom reaction injection molding and ready for tooling.

RIM PROCESS COMPARISON

11 IMPORTANT CONSIDERATIONS

| Complex, 3-dimensional Parts? |

| Self-Supporting, Structural Parts? |

| Thin & Thick Wall Sections in same part? |

| Mold Very Large Parts? |

| Easily Mold Deep Draw Parts with Ribs? |

| Tooling Costs & Materials |

| Prototype Tool to be Production Tool |

| Material Versatility? Foam/ Solid? |

| Easily Encapsulate Components and Attachment Points? |

| Annual Production Rates? |

| In Essence: |

| RIM Process | Injection Molding | Thermoforming Vaccum Forming | Cast Metal | Sheet Metal |

|---|---|---|---|---|

| YES - a "Sweet Spot" for RIM | YES | LIMITED | YES | VERY LIMITED |

| YES, polyurethane structural foam is ideal for this application | LIMITED, for small parts only | NO, requires structrual frame | YES | NO, requires structural frame |

| YES - easily mold thin and thick part geometries without sink marks or warp using polyurethane structural foam. | NO - very limited wall thickness variation | NO - very limited wall thickness variation | YES - but sink marks are common | NO - must weld various parts thickness together |

| YES, a RIM "Sweet Spot" | YES, but extremely high tooling and equipment expense | YES for simple geometries | YES, but very expensive | YES, but requires multi-step assembly |

| YES | LIMITED | LIMITED - thinning of material due to stretching | YES | NO |

| Low tooling investment using primarily aluminum but also lower cost materials | high to very high investment - using mostly steel | moderate to expensive - using a variety of materials | moderate to expensive | low to very expensive - limited to steel due to pressures if forming is required (stamping) |

| YES - low cost tooling can be used for prototype and production | LIMITED - can add cavities under certain circumstances | LIMITED - can add cavities under certain circumstances | LIMITED | LIMITED |

| Highly Versatile range of foam and solid materials resulting in broad range of part characteristics. Can mold foam or solid materials with same equipment | VERY LIMITED - requires separate tooling and equipment for foam and solid | NO | NO | NO |

| YES - metal hardware, magnets, antennas, batteries, electronics, PCB's can be encapsulated right into the molded part. | LIMITED - to hardware only | NO | NO | NO |

| Low to medium high | Medium high to extremely high | Low to medium | low to high | low to medium |

| Polyurethane structural foam makes RIM a very versatile process for parts the size of your phone to an MRI machine in medium production volumes. The bigger and more complex, the better. THINK: what can be molded in place instead of being assembled? Including the supporting frame. | great for small parts and high volume production. | for simple skins without structural function | well suited for heavy duty machinery | ... if you just need a box ... |

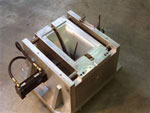

THE IMPORTANCE OF TOOLING

While you need good tooling to make high-quality parts, it does not have to be expensive.

Rimnetics has built hundreds of tools for the most diverse applications, each one with its unique requirements, budgets, and timelines. Whether you are looking for tooling that will last for a lifetime or for tooling that needs to last for a limited run or low annual volume, Rimnetics has several tooling options. We also have low-cost tooling to meet the needs of your project.

Our custom RIM molding and engineering process does not require steel tools. Machined aluminum is the highest-grade tooling necessary and at Rimnetics, it is guaranteed for unlimited shots. Our tool shop is located in Loomis, CA in the same facility where we also do molding. This allows tool adjustments to be made quickly and First Article parts to be molded in the shortest possible time.

More than once, prospective customers have asked Rimnetics to take over foreign-made tooling, improve the tools, and make the project work specifically for them. We can do that for you, too.

NOT SURE WHAT KIND OF VOLUMES TO EXPECT FOR YOUR PROJECT?

One of the most important questions to decide when purchasing a tool is “How many units can we expect to sell per year?” This can be a very difficult to answer and being wrong can be expensive. Our RIM molding design comes with a very low tooling investment. It allows you to get your product to the market quickly and at much lower risk than the tooling needed for injection molding. In economically challenging times that is a very good thing.

© 2023 Rimnetics, Inc. Loomis & Morgan Hill, California | Rimnetics is ISO 9001:2015 Certified