STRUCTURAL ENCLOSURES

SRIM & CUSTOM REACTION INJECTION MOLDED ENCLOSURES

CUSTOM STRUCTURAL REACTION INJECTION MOLDING

Structural Reaction Injection Molding (SRIM), a variant RIM process that adds structural elements to the mold prior to injection, provides ‘one-piece’ solutions for your enclosures and structural parts. Rimnetics employs this technique to create strong and lightweight composites. Polyurethane, the most common material created by the standard RIM process, is injected into the pre-strengthened mold (tool) at a very low viscosity where it chemically reacts and cures. Since such a low-viscous material exerts very little stress on the tool, our structural reaction injection molding process can make large and complex 3-dimensional parts at a fraction of the tooling investment of a comparable injection molding tool. While a custom reaction injection molded enclosure is not necessary all the time, it is an important tool to have available to meet your project goals.

WHY IS SRIM SO DIFFERENT?

Structural Enclosures

Design the skin so that it becomes the structural support - "unibody design"

Cosmetic and Functional Parts Become One.

Combine free-flowing geometries with functions like attachment points

Overmolding and Encapsulation

Reinforcements or attachment hardware, electronic components, magnets, batteries, or antennas can be molded right into the RIM part.

SRIM/RIM EXAMPLES

A PRECISE FIT

This unit consists of 13 individual RIM parts that all must fit together precisely in this assembly. Complex assemblies like this peripheral equipment for an MRI machine are not a problem in RIM.

NEED A BETTER SOLUTION THAN SHEET METAL?

Are you thinking of a sheet-metal-skin-on-frame concept for your injection molded enclosure? Why not make the skin also serve as the structural frame? Reaction injection molded enclosures eliminate one entire manufacturing step. Here is a great example of a “skin” with free-flowing curves that is also the structural component. Polyurethane Structural Foam can reduce your total manufacturing cost by reducing the number of parts and assembly time.

MEDICAL CARTS

Carts are great matches for the SRIM process. They often combine the demand for an elegant industrial design, complex geometry, structural requirements to support the weight of the unit, as well as an impact resistant surface. Components are designed and molded as a single piece that otherwise would have to be assembled from several parts. Free-flowing curves are easily achieved with Rimnetics’ tooling and molding expertise. When Form Follows Function, Rimnetics follows Form.

NEED LARGE PARTS?

Not a problem with RIM. One of the key advantages of the RIM process is the low viscosity of the material injected into the mold. The low pressure during injection allows for very large but complex parts, made from low-cost tooling.

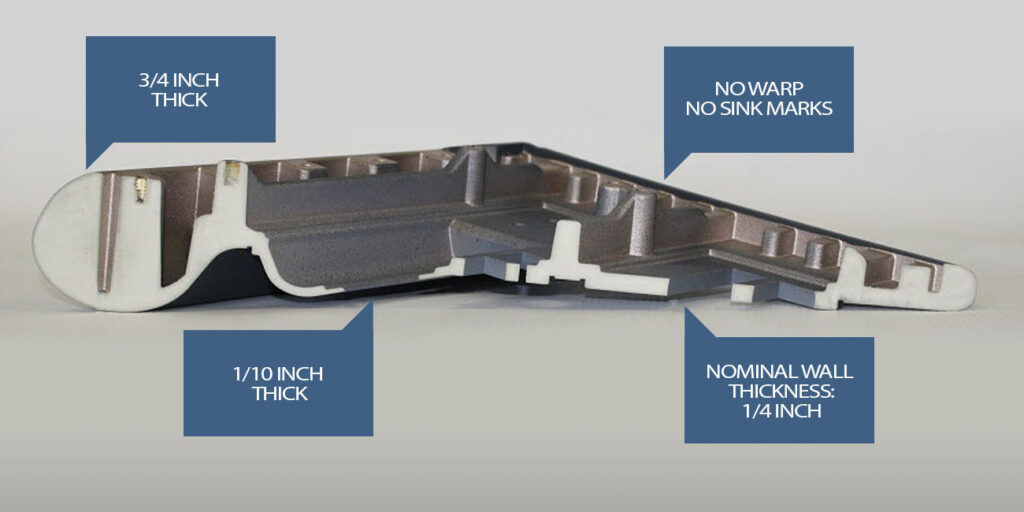

TRY THIS WITH STANDARD INJECTION MOLDING!

As a designer, you may be used to the common restriction of designing a plastic part with a uniform nominal wall thickness, reinforcement ribs at some percentage of that thickness, and bosses cored out to the bottom. Well, imagine the freedom of design at your disposal if you no longer have to live with these restrictions. Imagine how much simpler the part design can become, how many corners, nooks and crannies in the geometry can be filled in. How much quicker a tool ready design can be achieved and how much faster and cheaper that tool can be made. All of the above is possible with our polyurethane structural foam molding – a solid skin, foamed core sandwich structure that allows you to vary the wall thickness within the same part. Not only will this approach result in the advantages above, but in a much more rigid and self-supporting design.

MEDICAL DEVICE ENCLOSURES

This is one of Rimnetics core markets. No matter if it is a DNA sequencer, a sample analyzer, or any other medical device, RIM achieves all of its advantages here. With various materials, rated UL94-V0 for flammability, all key requirements for these kinds of parts are being met: Complex, 3-dimensional parts, with appealing industrial design, manufactured at medium high volumes – perfect for RIM.

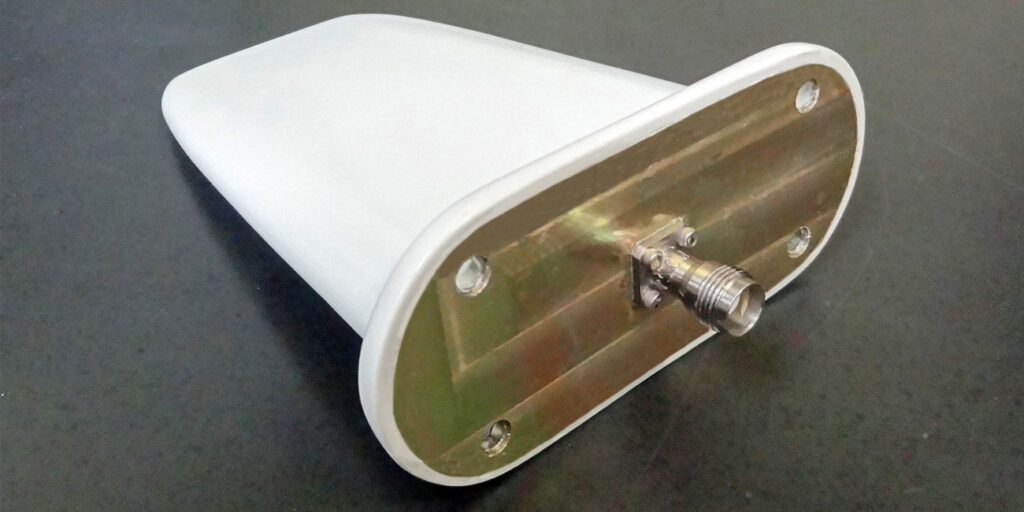

OVERMOLDING

What if you only need a certain area overmolded, as in this antenna? Since polyurethane is a natural adhesive, it is ideal for just this kind of application overmolding. As in this example, the hardware is inserted into the mold and polyurethane is injected only in defined areas, leaving the other areas exposed.

GAMING MACHINE

Gaming machines, ATMs, and vending kiosks are other great examples of custom reaction injection molded enclosures. Since they are often large in format and run in medium production volumes, the low tooling investment available from Rimnetics make them ideal matches for our process.

FREEDOM OF DESIGN

Feel free to create free-flowing curves, detailed geometries combined with structural and functional qualities in your part. The RIM material injected into the mold at a very low viscosity will carefully fill out even the most delicate geometries. Rimnetics Engineering will guide you through the steps to construct a RIM feasible design in order to make your new project a show piece.

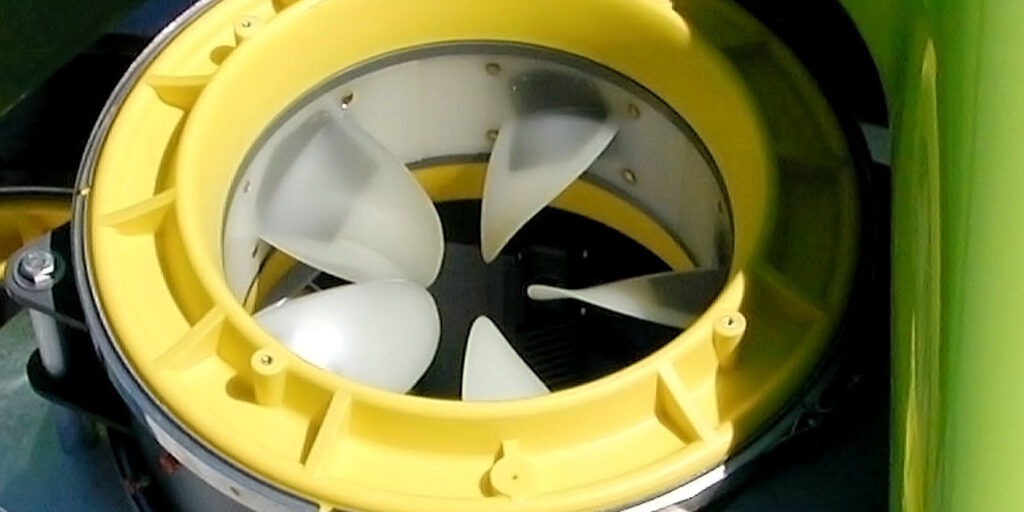

SUBSEA AND MARINE APPLICATIONS

Subsea and Marine Applications like this propulsion system for a deep-sea submersible are ideal candidates for the SRIM process. Not only is the polyurethane material salt water resistant, it can also seal and encapsulate other components into your part. In this example, rare earth magnets are encapsulated as part of the electric motor. If a Polyurethane Structural Foam is used instead of a solid polyurethane, the molded part even becomes buoyant.

RIMWOOD™

Rimwood is an attractive and durable wood replacement product. It captures the high surface hardness of RIM (reaction injection molded) polyurethane.

Rimwood is used as a substitute for wood in numerous products such as exterior door and window trim as well as unlimited interior and exterior millwork profiles. Rimwood incorporates functionality with aesthetics to enhance the appearance of any newly constructed or remolded home. Rimwood is simple to install and exterior applications will maintain their attractive appearance far longer than traditional wood or extruded PVC trims.

RIMWOOD™

with its crisp detailed profiles, can enhance the appearance of any new home and help maintain traditional high-quality architecture to any remodeling project.

is “in-mold” painted which, through molecular bonding, delivers exceptional paint adhesion and color retention that prevents peeling and blistering common to exterior wood finishes.

will not rot as does wood when subject to moisture.

polyurethane chemistry is free from any insect infestation.

with its high surface hardness is highly resistant to impact damage.

trim profiles are designed with built-in, hidden fasteners that allow for effortless installation, eliminating nail hole blemishes.

trim is designed to integrate into window and door frames so you never end up with a “tacked-on” look.

utilizes traditional carpentry tools and fasteners for installation because it saws and machines like wood, and can be nailed and screwed like wood.

is available in colors to match most major window and door brands.

with its ease of installation and virtually no maintenance, is a very affordable wood replica option.

© 2023 Rimnetics, Inc. Loomis & Morgan Hill, California | Rimnetics is ISO 9001:2015 Certified