The Benefits of Low-Pressure Overmolding Electronics

Low-pressure overmolding is a manufacturing process that utilizes low temperatures and pressures to mold components directly into a part. Due to its usage of reduced pressures, the process offers a wide range of advantages that can enhance the capabilities of the final product. While low-pressure overmolding can be applied to a variety of components, the process is especially beneficial for molding electronic components into products. To better understand the advantages of low-pressure overmolding electronics, continue reading.

AVOID DAMAGE TO SENSITIVE COMPONENTS

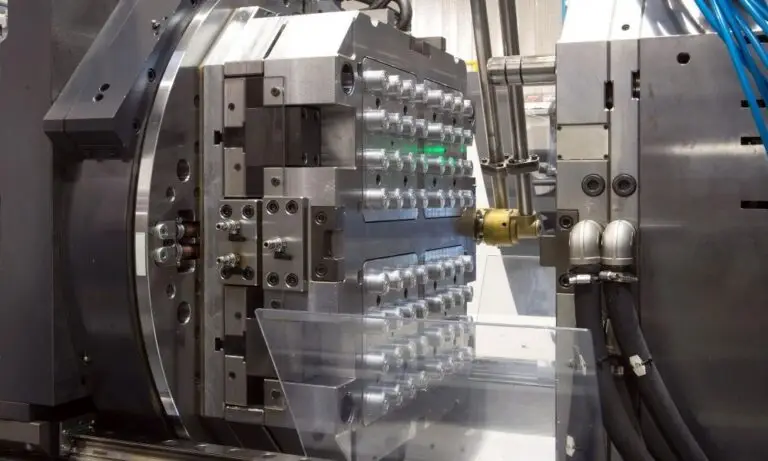

Low-pressure overmolding is particularly well-suited for injection molding electronic items because the process applies less force when injecting its plastic material into the mold and is therefore significantly less likely to damage fragile components. By comparison, traditional overmolding can be problematic because it requires extreme temperatures and pressures that often endanger delicate equipment. For this reason, low-pressure overmolding can be particularly beneficial for safely encapsulating electronics into a molded part.

PROVIDE ENHANCED ENVIRONMENTAL PROTECTION

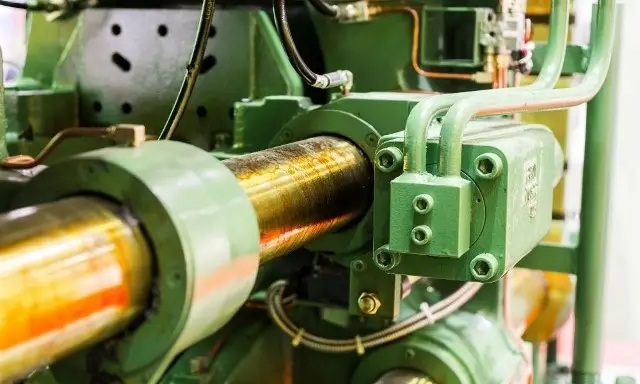

Low-pressure overmolding with RIM is also advantageous when encapsulating electronics because the process allows for any electronic item to be surrounded by a durable layer of polyurethane that protects the device without limiting its functionality. Due to this added layer of seamless protection, electronics can maintain their performance despite being exposed to chemicals, high temperatures, rain, wind, or other harsh environmental conditions.

IMPLEMENTING AND STRENGTHENING WIRELESS CAPABILITIES

Another benefit of low-pressure overmolding electronics is the process allows you to implement and even strengthen the wireless capabilities of a device into a molded part. When low-pressure overmolding an antenna or other electronic device into a part, the polyurethane shell that is created around the wireless device is less dense and restrictive than those created by higher pressure injection molding methods. As a result of this lower density, any radio signals from wireless components will be able to travel farther.

If you’re interested in implementing low-pressure overmolding to mold an electronic device into your part, Rimnetics can help. One of the most popular molding processes for carrying out low-pressure overmolding is reaction injection molding. Due to the low viscosity of the materials used in the process, high temperatures and pressures aren’t required to force the material into the mold. As such, it is an ideal option for low-pressure overmolding. To learn more about electronics injection molding, contact us today.