REACTION INJECTION MOLDING COST

Reaction injection molding (RIM) stands out for its efficiency and cost-effectiveness, particularly in the realm of producing large and intricately designed parts. A significant advantage of this method lies in its relatively low tooling costs. Compared to traditional methods, RIM requires a lower injection molding equipment cost, which substantially lowers the entry barrier for production. Additionally, this process is synonymous with low-cost injection molding due to its minimal waste and faster production times. Manufacturers can achieve high-quality outputs with reduced financial outlay, making RIM an attractive option for a wide range of industries seeking cost-effective manufacturing solutions.

There are several important factors to consider when choosing a production process for your manufacturing project. Design flexibility, process efficiency, process duration and cost represent major decision criteria for manufacturers. Choosing a process that will save money and is well-suited to one’s budget during all stages of the part’s lifecycle is imperative for the success of any project. Below, we will discuss the reaction injection molding cost for the manufacturing process as well as the financial benefits.

RIM SIMPLIFIES THE PRODUCTION PROCESS

Reaction injection molding’s ability to produce large parts and mold-in attachments allows the product to be constructed without having to create and attach multiple parts. In other words, products like medical devices, previously consisting of multiple parts can be designed as a single part when incorporating RIM’s design and production concepts. By combining two or three separate parts into one part, reaction injection molding helps simplify the manufacturing process significantly. Some of the many financial benefits of decreasing the total number of parts produced include:

ASSEMBLY COSTS

In reducing the complexity of the part production process, RIM reduces the need for post-production assembly processes. Because such processes can significantly increase the completed part’s production cost, reducing or eliminating these processes by utilizing reaction injection molding can help cut back on manufacturing costs.

REDUCING NUMBER OF SUPPLIERS

Supplier consolidation is another benefit of reducing the number of components within a part. There are several reasons why eliminating suppliers throughout the manufacturing process may be economically advantageous.

DECREASED PURCHASING COSTS

Supplier consolidation can help decrease purchasing costs. In decreasing one’s supplier base, one’s purchasing power increases as more resources can be acquired from a limited number of suppliers. In doing so, manufacturers can often obtain better prices for parts and reduce the handling costs or other related shipping fees that can quickly add up when purchasing from a larger number of suppliers.

DECREASED PROCESSING COSTS

Reducing the number of suppliers can also reduce processing costs. By decreasing the number of suppliers, transactional costs, such as the price of setting up suppliers in internal systems or managing supplier relationships subsequently decrease. Further, the time saved by consolidating these responsibilities can be focused on higher priority goals that ultimately increase revenue.

FEWER COMPONENTS TO STOCK

Reducing the complexity of a part’s design also means that there are fewer components that need to be stocked. Thus, reaction injection molding, which allows the manufacturer to reduce each part’s total number of components, can help reduce the time needed to stock parts and potentially free up storage space. In saving time and minimizing the amount of space required, RIM subsequently helps reduce labor and storage costs.

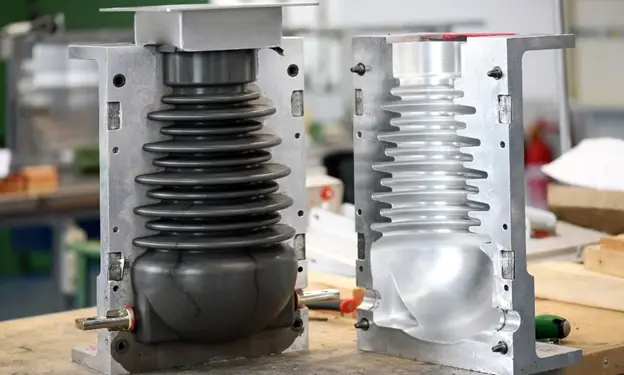

RIM HAS LOW TOOLING COSTS

Reaction injection molding also has much lower tooling costs than other part production processes, such as injection molding, which helps lessen the manufacturing cost of larger, more complex parts that are produced in lower volumes. Tooling costs are so much lower for RIM because the polyurethane mixture used in the RIM process has a low viscosity that only needs relatively low pressures and temperatures to mold it to the tool.

Since the tool does not need to withstand intense temperatures and pressures, it can be machined from low-cost aluminum rather than expensive metals such as steel. In creating molds from aluminum rather than steel, the tooling cost of a part is lowered by tens or even hundreds of thousands of dollars. When producing parts in low volumes or parts requiring a sizable tool, the lower tooling cost of RIM makes it a financially advantageous option.

RIM PARTS HAVE A SELF-SUPPORTING STRUCTURE

RIM can be beneficial for a range of industries because it is a process that creates parts with a unibody support. RIM’s capacity to construct parts with self-supporting structures empowers engineers to consolidate components and simplify their designs. Rather than installing an internal metal frame to support the various components of a part, a RIM part supports itself with the external surface serving as the internal frame. As a result, assembly time is decreased and manufacturers can save on material costs, which yields an overall lower part manufacturing cost.

If you are interested in exploring the financial benefits associated with reaction injection molding for your manufacturing project, Rimnetics, Inc. is happy to help. We are North America’s premier reaction injection molding for encapsulation, enclosures, structural parts, cosmetic housings, and overmolding. With over 30 years of experience, Rimnetics intimately understands the art of providing molded solutions® to a variety of industries including the medical device, electronics, construction, defense, IT, and laboratory equipment fields. To learn more about how Rimnetics, Inc’s reaction injection molding process can help you produce superior parts at the lowest possible price, please contact us today.