Compression Molding vs. Reaction Injection Molding

Compression molding and reaction injection molding are both utilized to create a wide range of molded parts. These processes share a few similarities, such as their ability to create larger parts and their low-to-medium-size production volumes, but they also possess several distinct attributes. To learn about the key differences between compression molding versus reaction injection molding and choose the right process for your purposes, continue reading.

THE PRODUCTION PROCESS

The primary differentiator between compression molding vs reaction injection molding is their production processes. Below, we will highlight the dissimilarities between the two methods.

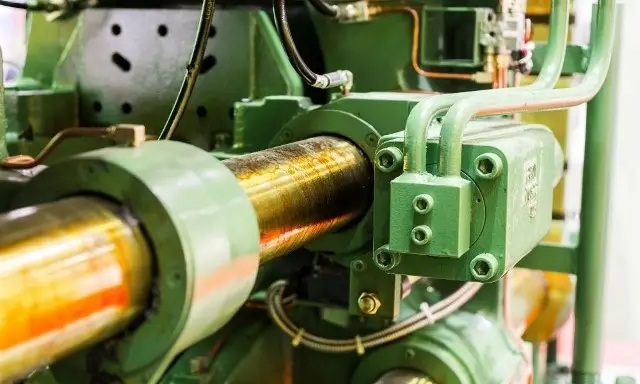

THE COMPRESSION MOLDING PROCESS

The compression molding process involves placing raw plastic material into a heated mold cavity. The mold then closes, and plugs are inserted into the top of the cavity to seal and pressurize it. The plastic is compressed into the desired shape due to the combined effect of heat and pressure from the mold. Once the plastic has cured and the material has cooled down, the final part can be extracted from the mold.

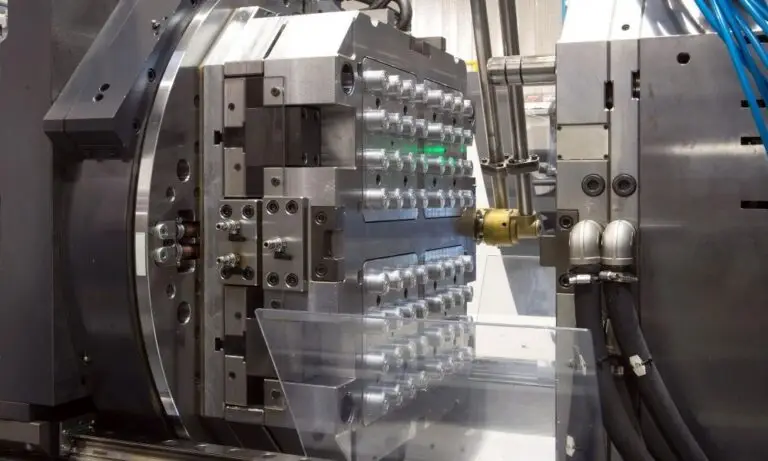

THE REACTION INJECTION MOLDING PROCESS

The reaction injection molding process involves combining two raw materials, polyol, and isocyanate. These materials are transferred into the mix head of a molding machine, where they are blended together to form a low viscosity liquid. This liquid is subsequently injected into a heated mold, where it undergoes an exothermic, or heat-generating, reaction. Owing to its low viscosity, the material requires significantly lower temperatures and pressures to conform to the tool compared to other popular molding processes. After the material cures, it is removed from the mold and then undergoes any necessary post-molding processing.

COMPLEXITY OF THE PART

Another noteworthy difference between compression vs reaction injection molding lies in the complexity of the parts they can produce. Compression molding often struggles to create parts with complex geometries, typically resulting in parts with a simpler, more block-like shape.

Reaction injection molding is widely known for its exceptional ability to create parts that have highly complex part geometries. Thanks to its high degree of design freedom, reaction injection molding can be used to create parts with varied wall thicknesses, encapsulated components, free-flowing curves, and other desirable design features.

When comparing compression molding versus reaction injection molding, remember that these molding processes employ different methods to create exactly what you need. Choosing Rimnetics to provide your reaction injection molding services ensures access to cutting-edge technology, unparalleled expertise, and bespoke solutions tailored to your specifications. Contact us and witness our dedication to quality, efficiency, and customer satisfaction. We pledge to complete your project on time, within budget, and beyond expectations.