How RIM Tooling Compares to Injection Molding Tools

The tooling used to create a molded part can substantially impact both your production process and final product. Therefore, it’s essential to carefully consider which type of injection molding will best suit your application before choosing a molding process. Two of the most popular part production processes that involve tooling include reaction injection molding (RIM) and injection molding. To better understand how their respective tooling processes compare, consult this side-by-side comparison.

STEEL VS. ALUMINUM

One of the primary differentiators between RIM tooling and injection molding is the material each process uses for tooling. While injection molding utilizes steel tools, RIM typically relies on aluminum tools. Detailed below is how many of the disparities between RIM and injection molding stem from their employment of slightly different tooling materials.

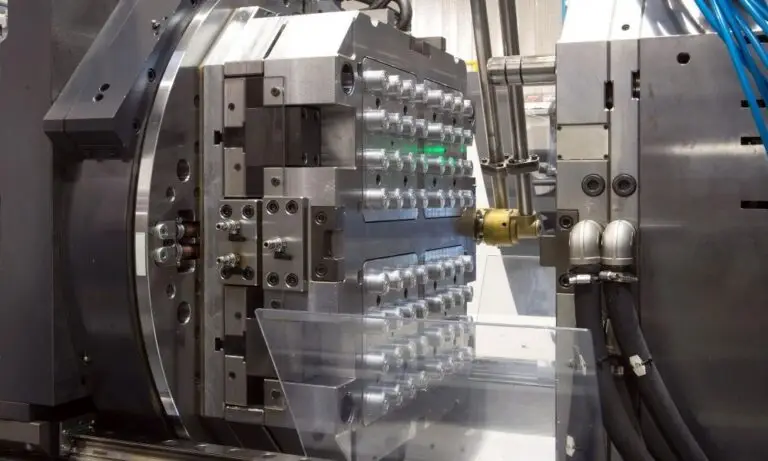

STRENGTH

Steel is an undoubtedly stronger and more durable material than aluminum. This is noteworthy because the injection molding process involves extremely high temperatures and pressures that necessitate the use of sturdy, robust tooling. Reaction injection molding utilizes far lower temperatures and pressures that do not require heavy-duty tooling.

COST

Aluminum costs far less than steel which means that injection molding tooling is typically far more expensive than RIM tooling.

When creating larger, complex parts, the cost of building a steel tool becomes exorbitant. In such instances, a RIM aluminum tool is the more cost-effective option.

DESIGN FREEDOM

Another important factor to explore when considering how RIM tooling compares to injection molding tools is design freedom. Aluminum is far more malleable and elastic than steel so it can be shaped into highly complex designs more easily than rigid injection molding tooling can.

For example, RIM tooling can be designed to create molded parts with varying wall thicknesses, elaborate features, curves, and encapsulated items. Such complexity would prove to be inordinately costly if rigid, expensive steel tooling was used. Thus, RIM tooling can be leveraged to provide manufacturers with increased flexibility and a higher degree of design freedom.

Rimnetics is a leading reaction injection molding company for over-molding, encapsulation, enclosures, structural foam molding, and cosmetic housings. To learn more about our processes and services, contact us today.